Brake Rotor Design Services for High Performance

Project Overview

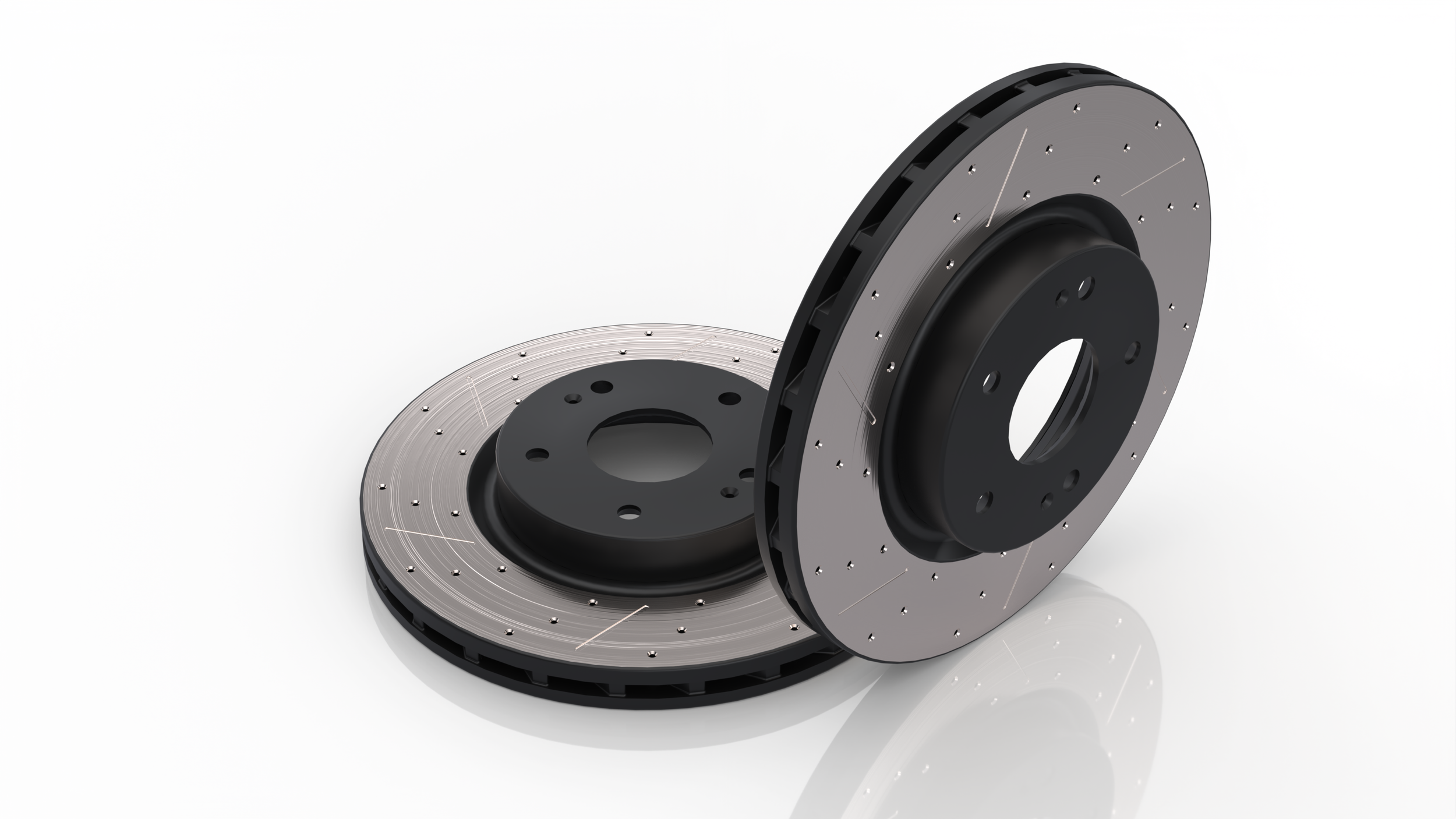

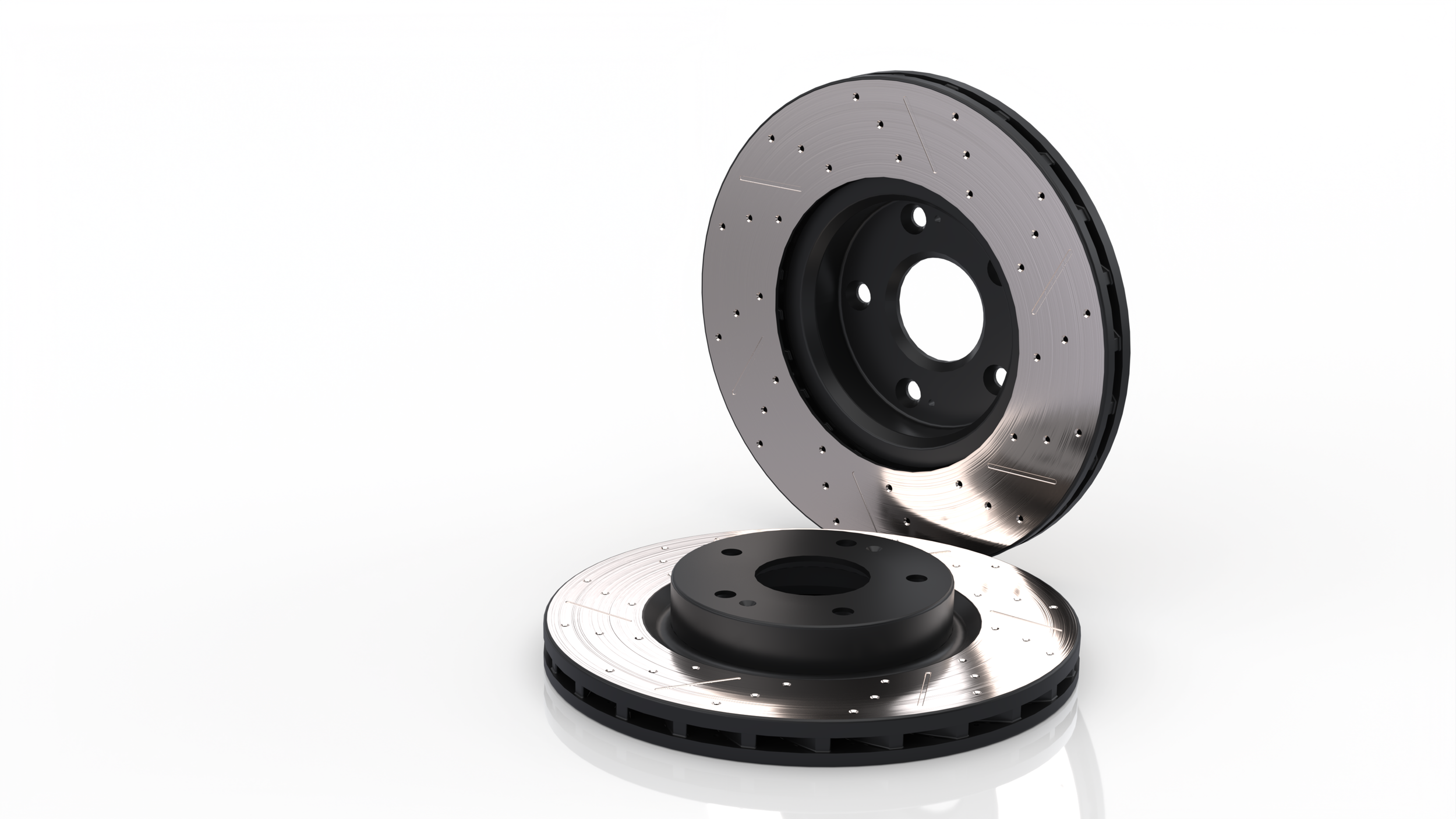

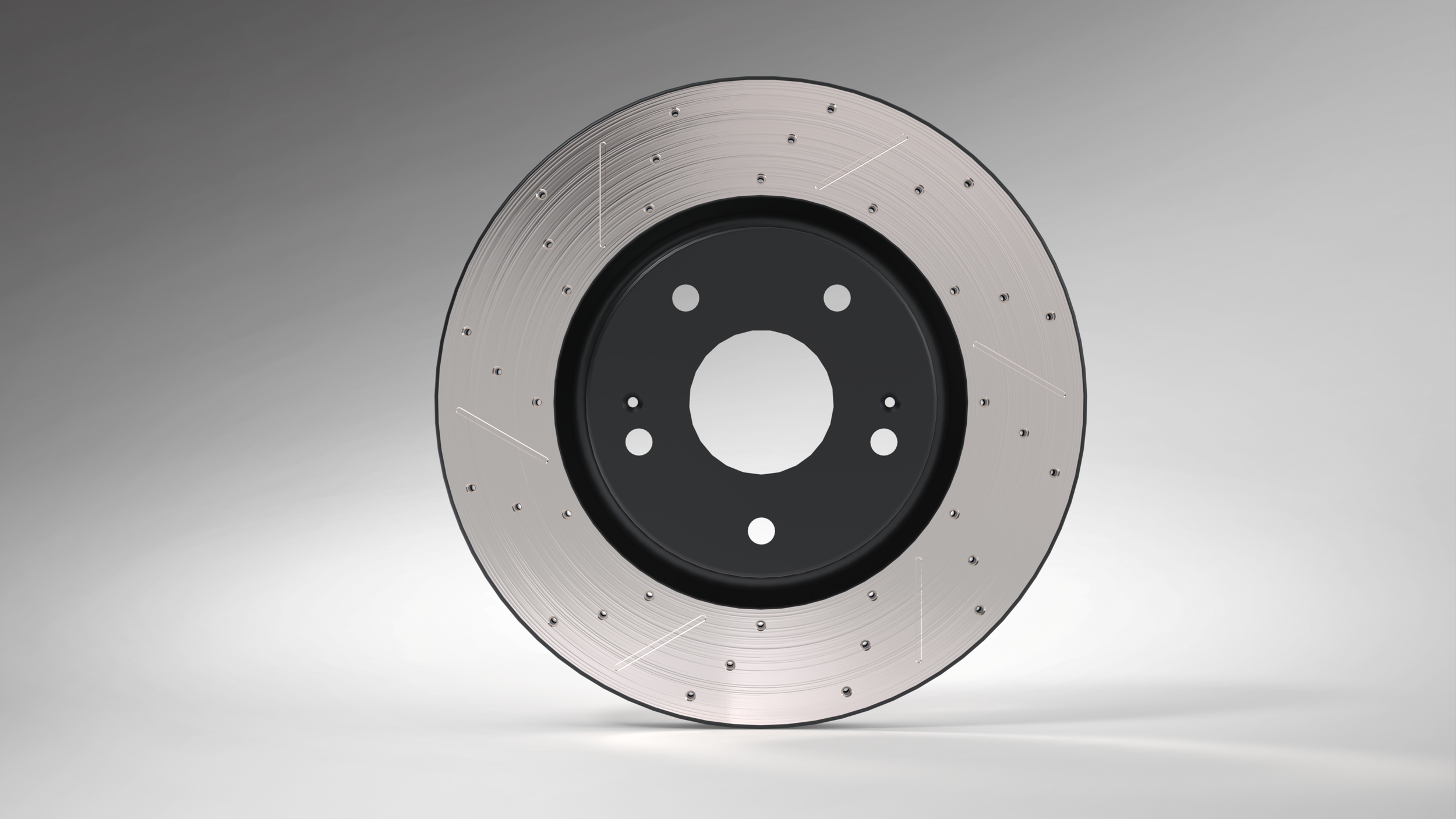

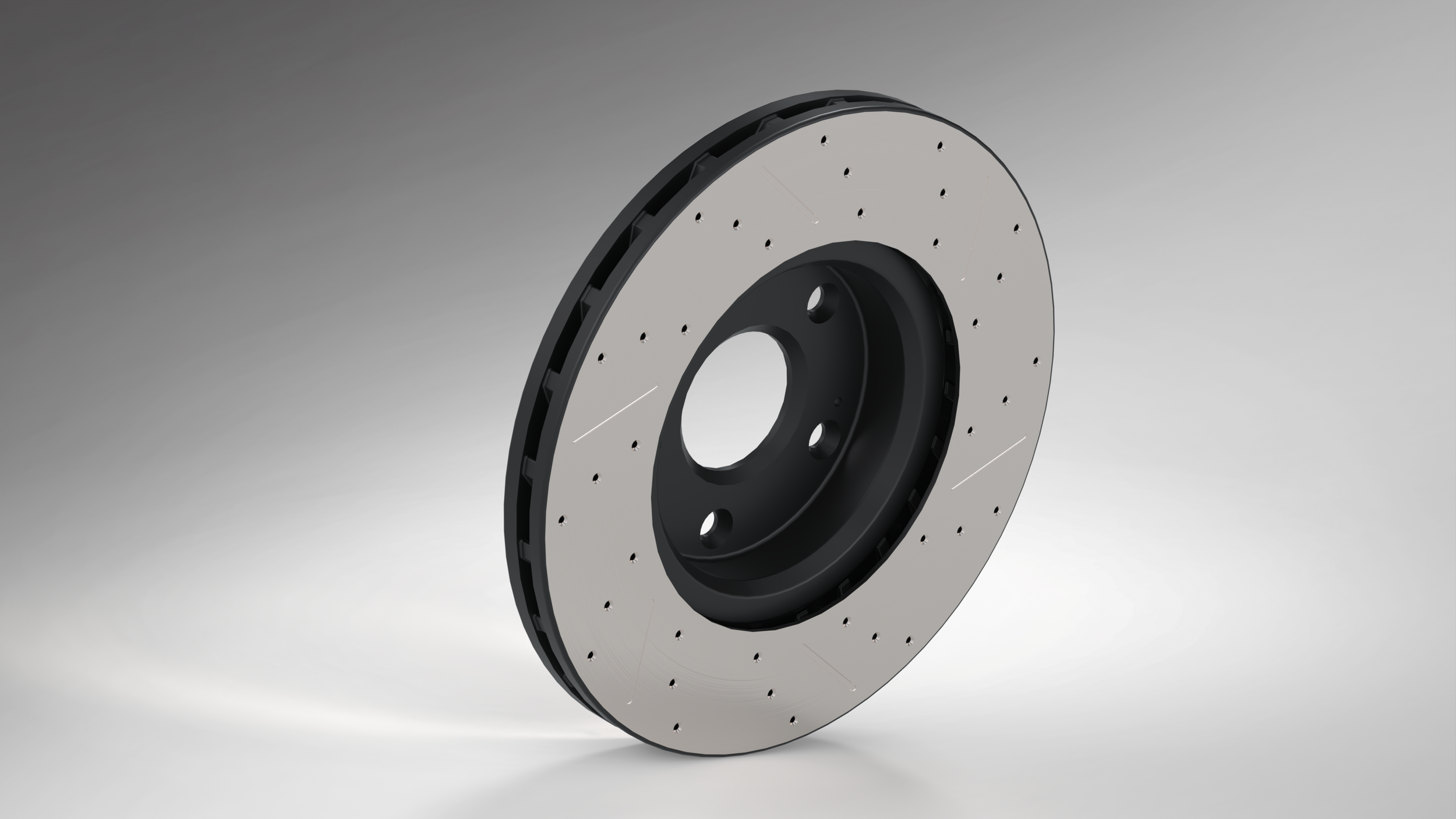

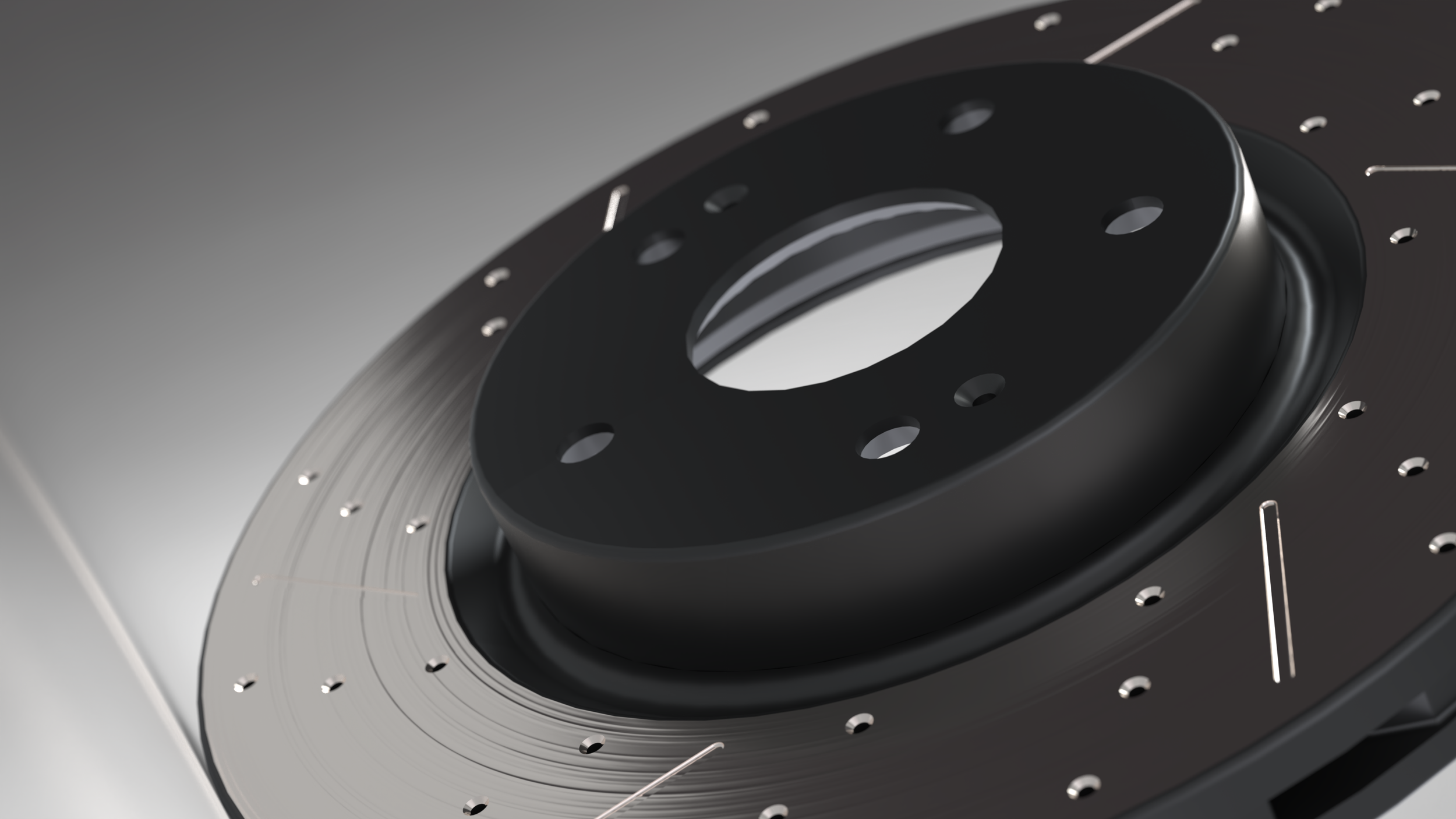

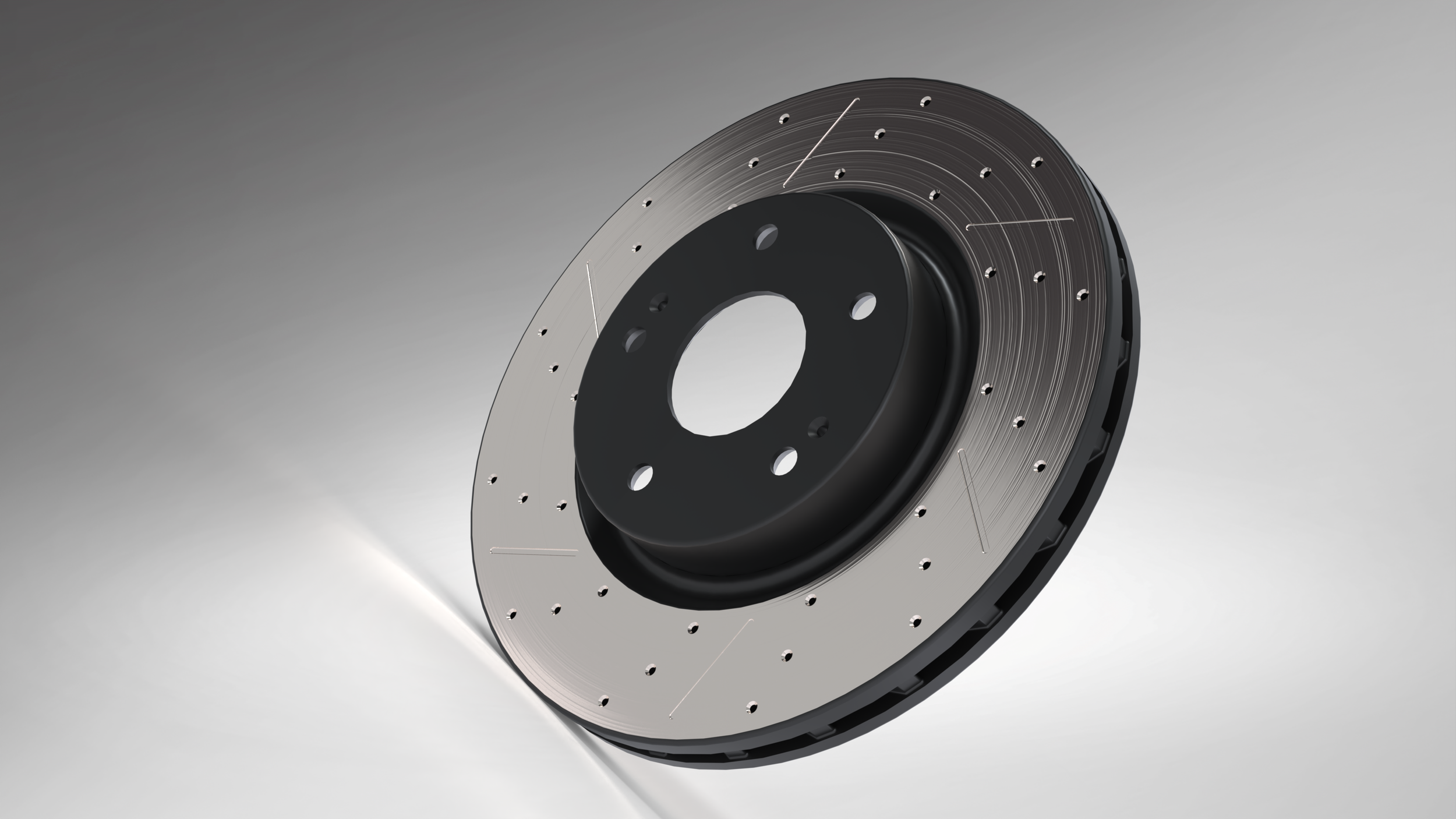

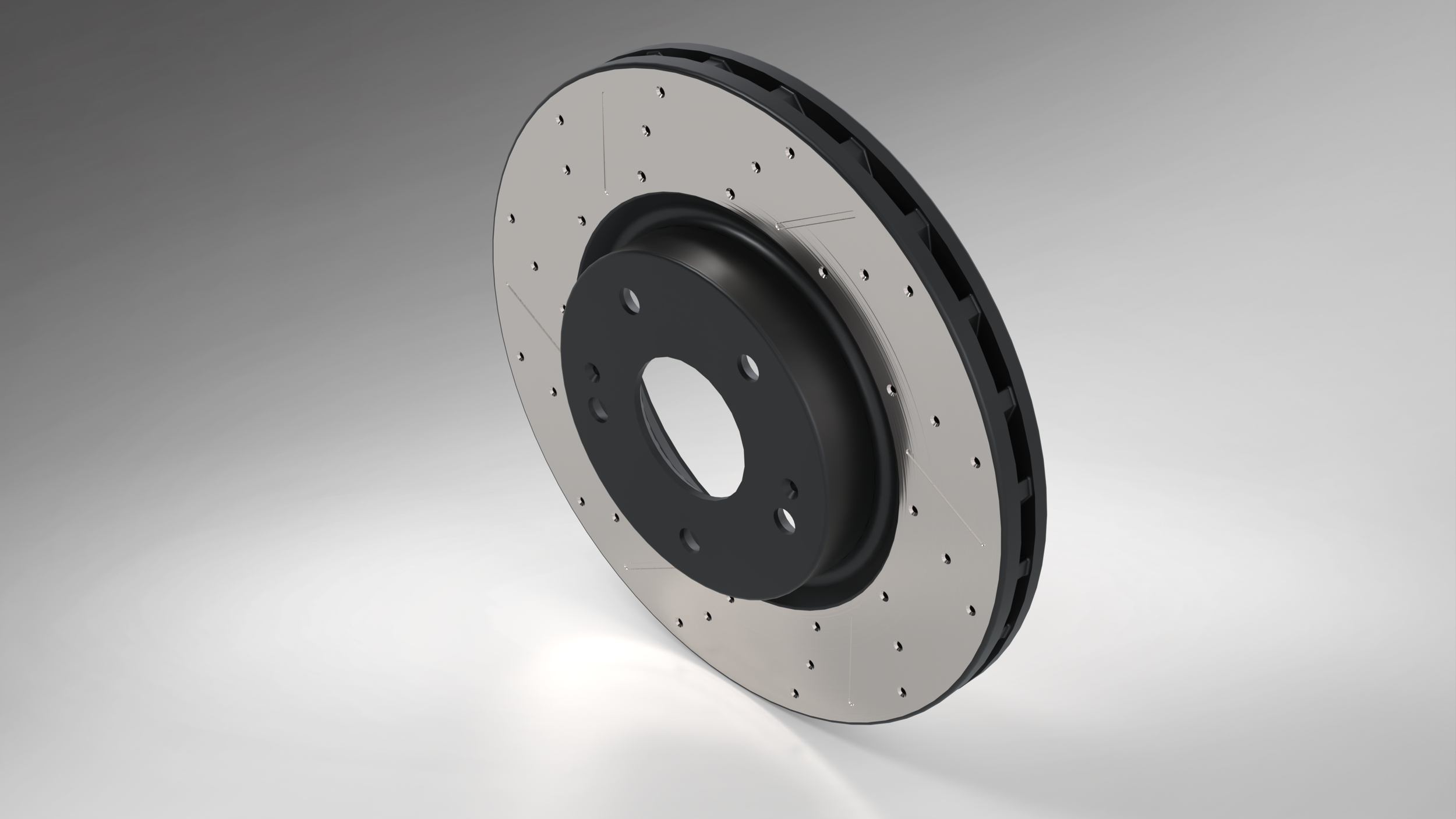

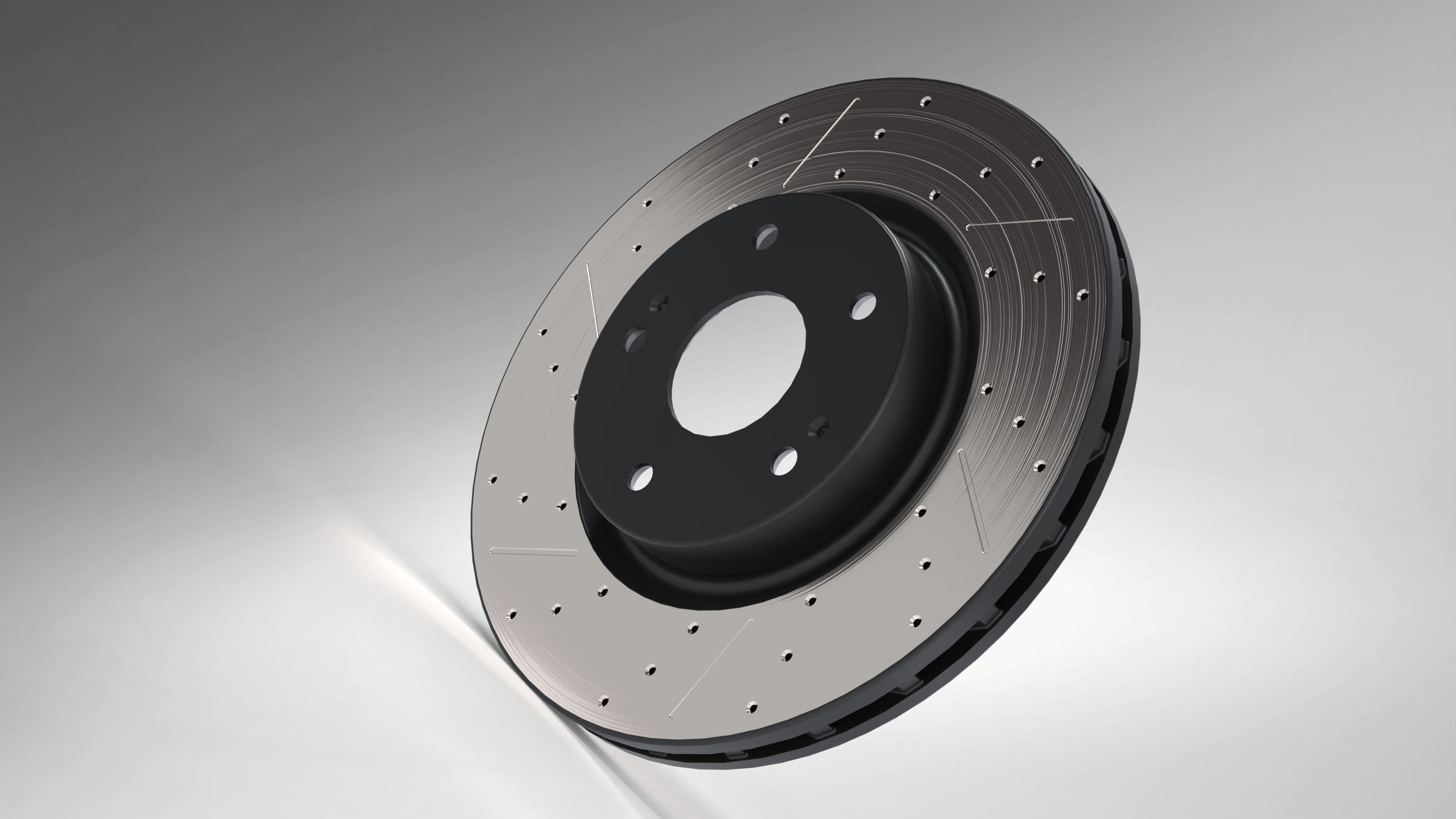

This high-performance brake rotor design was designed to improve braking efficiency, thermal management, and overall reliability under demanding conditions. Featuring a series of precision-drilled holes across its surface, the rotor enhances ventilation and reduces the risk of brake fade during repeated or high-speed braking. These holes also support a more efficient cooling cycle, helping the rotor shed heat much faster than solid alternatives. In addition, the pattern assists with the removal of water, dust, and loose debris, ensuring consistent contact between the brake pad and rotor in all driving environments, including wet or dusty conditions.

To support strength and long-term wear resistance, the rotor is modeled using a high-strength material commonly chosen for automotive braking components—cast iron. This material offers excellent thermal stability, predictable expansion characteristics, and dependable durability when exposed to repeated heating cycles. Every surface and transition in the model is carefully engineered to withstand the mechanical loads generated during aggressive braking.

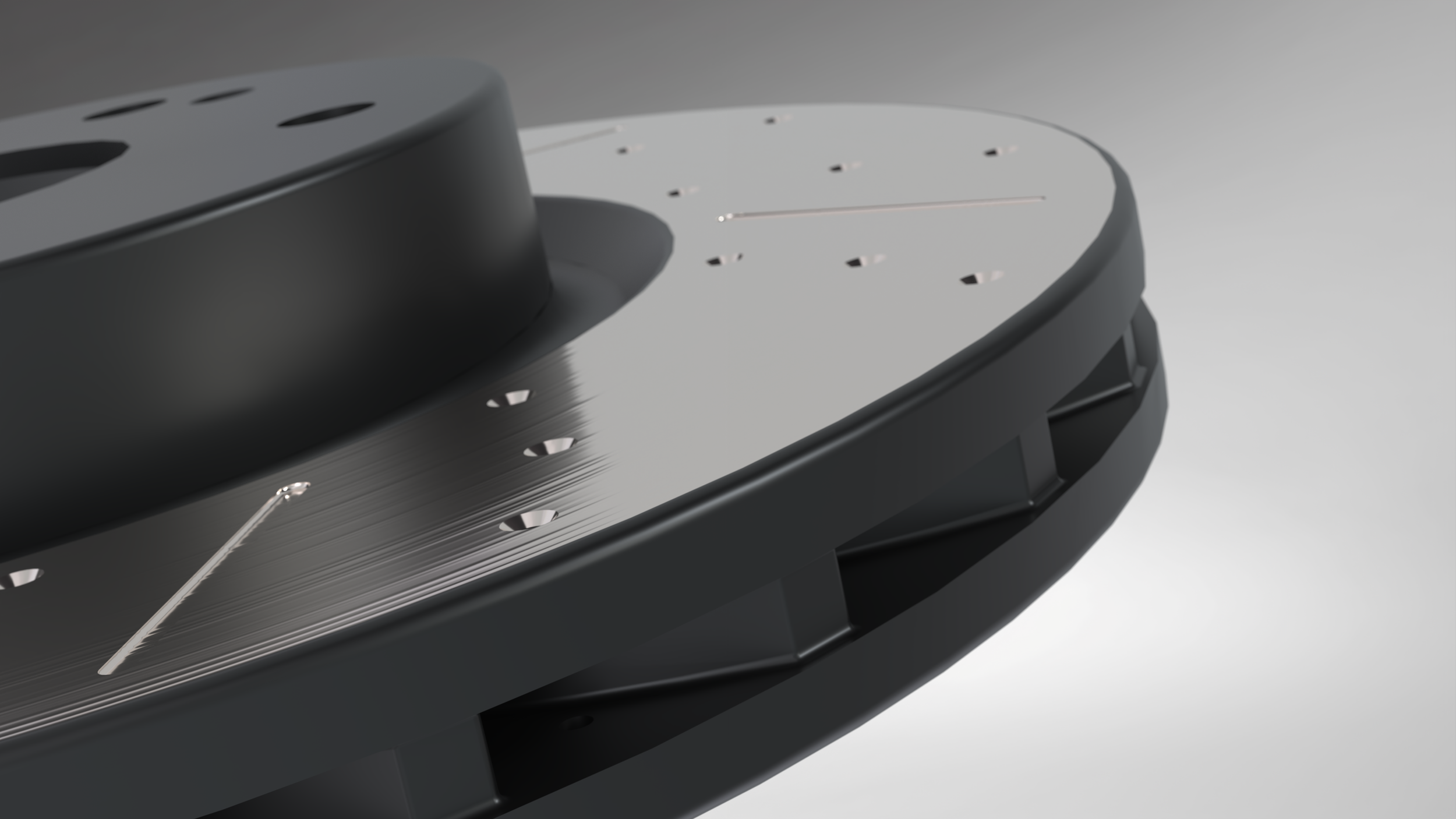

Additional slots along the outer edge further aid in heat dissipation and contribute to maintaining a clean braking surface. These slots continuously shave off glazing and buildup from the brake pads, promoting more consistent friction and improving overall braking feel. The geometry of each slot is optimized to manage airflow, encourage even wear, and reduce the likelihood of vibration or uneven pad deposits.

Taken together, the drilled and slotted features create a balanced design that supports both performance and longevity. The result is a brake rotor capable of delivering strong, reliable braking performance while minimizing thermal stress, reducing fade, and maintaining a stable, predictable braking response over time.

Design Highlights

Ventilation-Enhanced Geometry

Strategically placed cross-drilled holes improve airflow and reduce heat buildup during braking.

Precision CAD Modeling

Designed in SolidWorks with accurate dimensions, mounting hole placement, and material thickness for real-world compatibility.

Debris & Water Expulsion

Hole pattern and optional slotting help maintain clean contact between rotor and pad in wet or dirty conditions.

Material Consideration

Modeled for cast iron to balance durability, thermal performance, and manufacturability.