Bench Vise Design Services for Precision Tooling

Project Overview

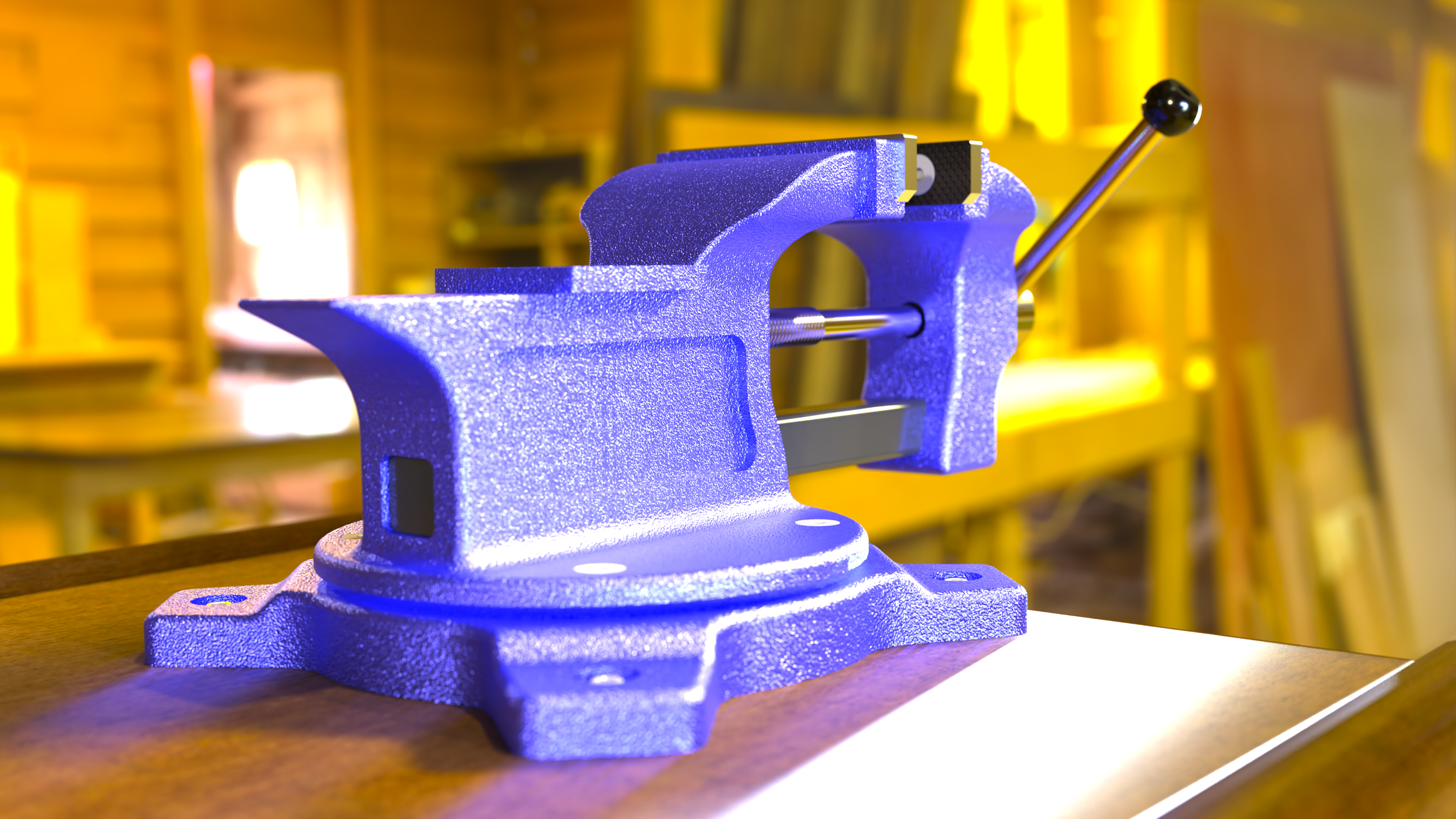

The objective was to design and fabricate a durable, versatile bench vise grip capable of securely holding a wide range of workpieces during mechanical, woodworking, and prototyping operations. The goal was to create a tool that could become a dependable fixture in both professional and hobbyist workshops, delivering stability, precision, and safety across a variety of tasks. Whether the user is cutting metal stock, drilling accurate holes, grinding uneven surfaces, filing edges, or assembling components, the vise is engineered to maintain a firm, reliable grip throughout the entire workflow.

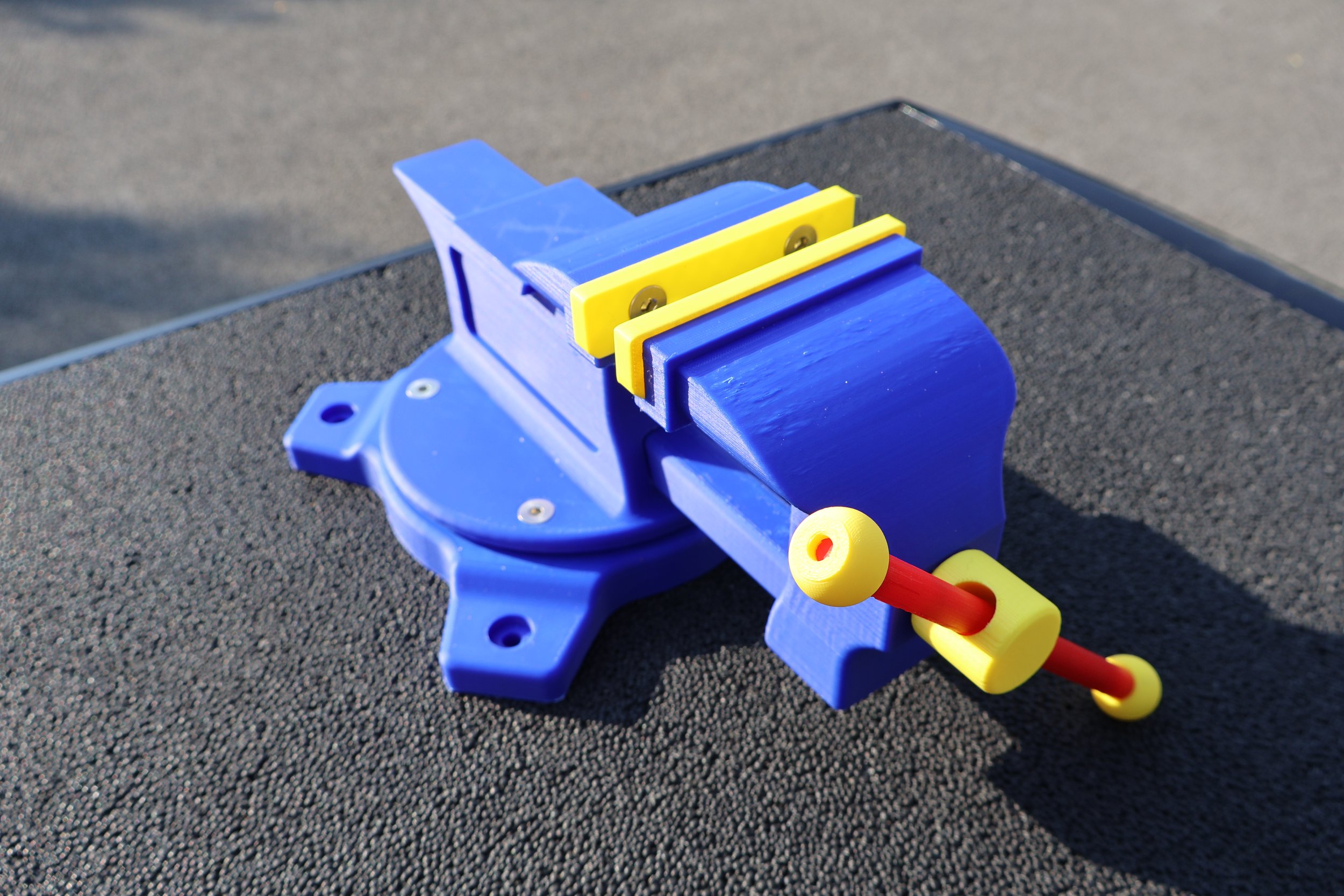

To achieve this level of performance, this bench vise design emphasizes structural strength and long-term durability. The vise incorporates reinforced geometry to withstand repeated clamping cycles and high mechanical loads. Its rotating base allows users to reposition the workpiece quickly without removing it from the clamp, improving efficiency during multi-angle or sequential operations. This rotation capability is particularly beneficial when switching between cutting, finishing, and inspection tasks.

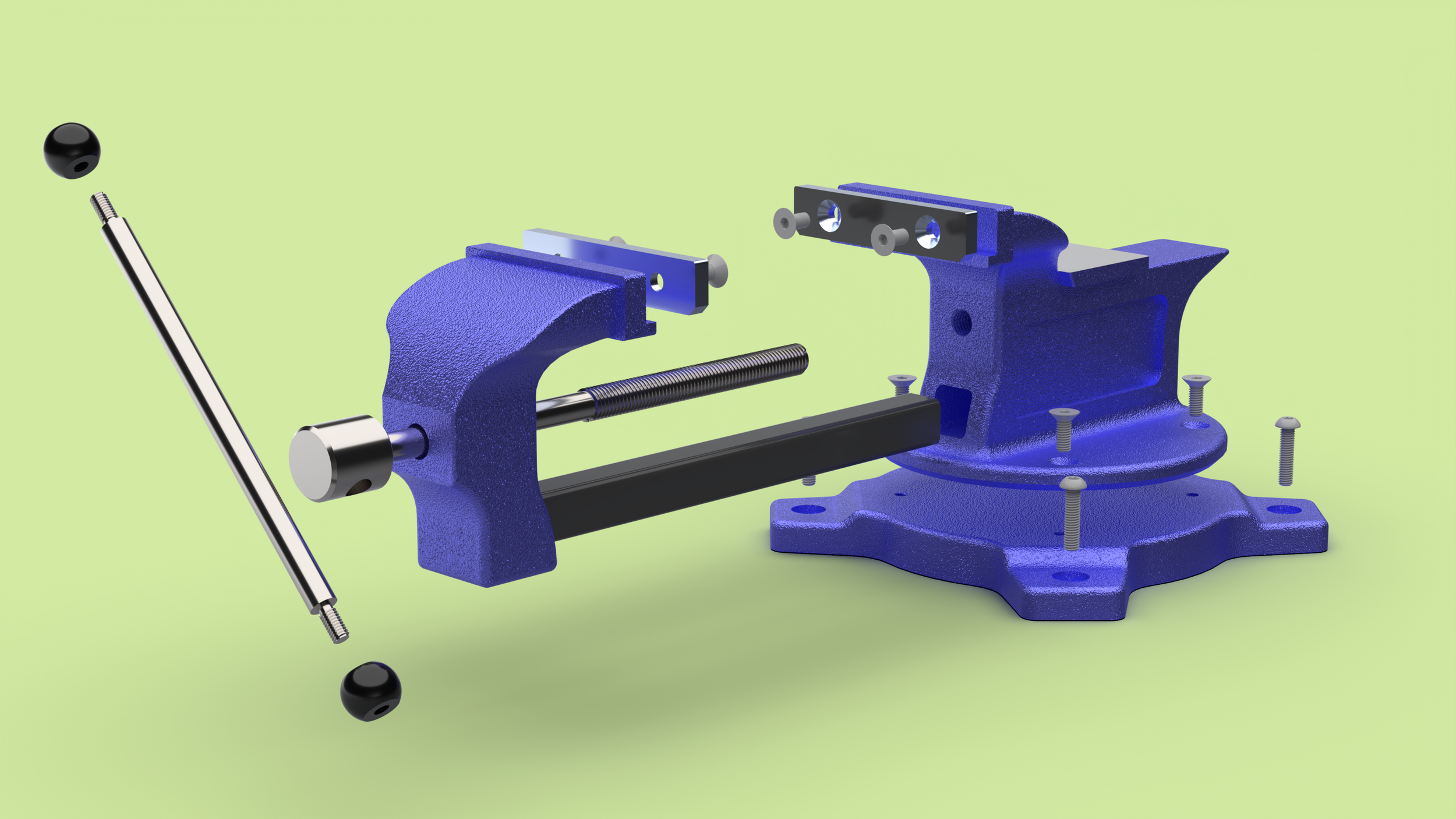

The vise features dual jaws equipped with protective inserts to prevent surface damage on delicate materials while still offering the grip needed for tougher applications. These replaceable inserts also extend the overall lifespan of the vise. The manual clamping mechanism is engineered for smooth, controlled operation, allowing users to apply consistent pressure with minimal effort. This design supports both light-duty tasks—such as holding small components for shaping or polishing—and heavy-duty operations that require strong, rigid clamping.

Additional considerations include ergonomic handling to reduce operator fatigue and careful attention to materials that balance weight, strength, and cost. The final design offers a practical blend of robustness, versatility, and user-focused functionality, making it suitable for a wide range of workshop environments and project types.

Design Highlights

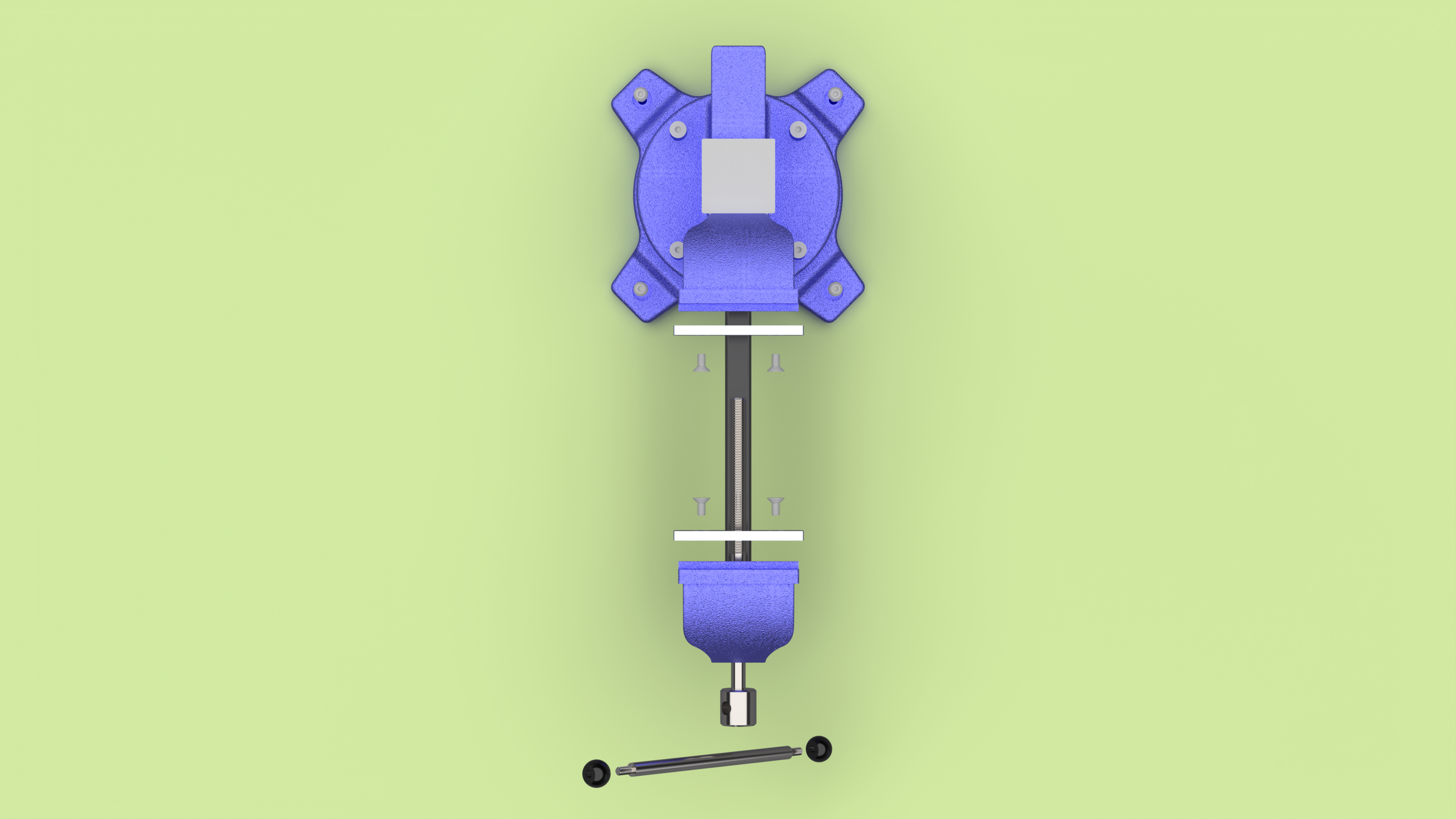

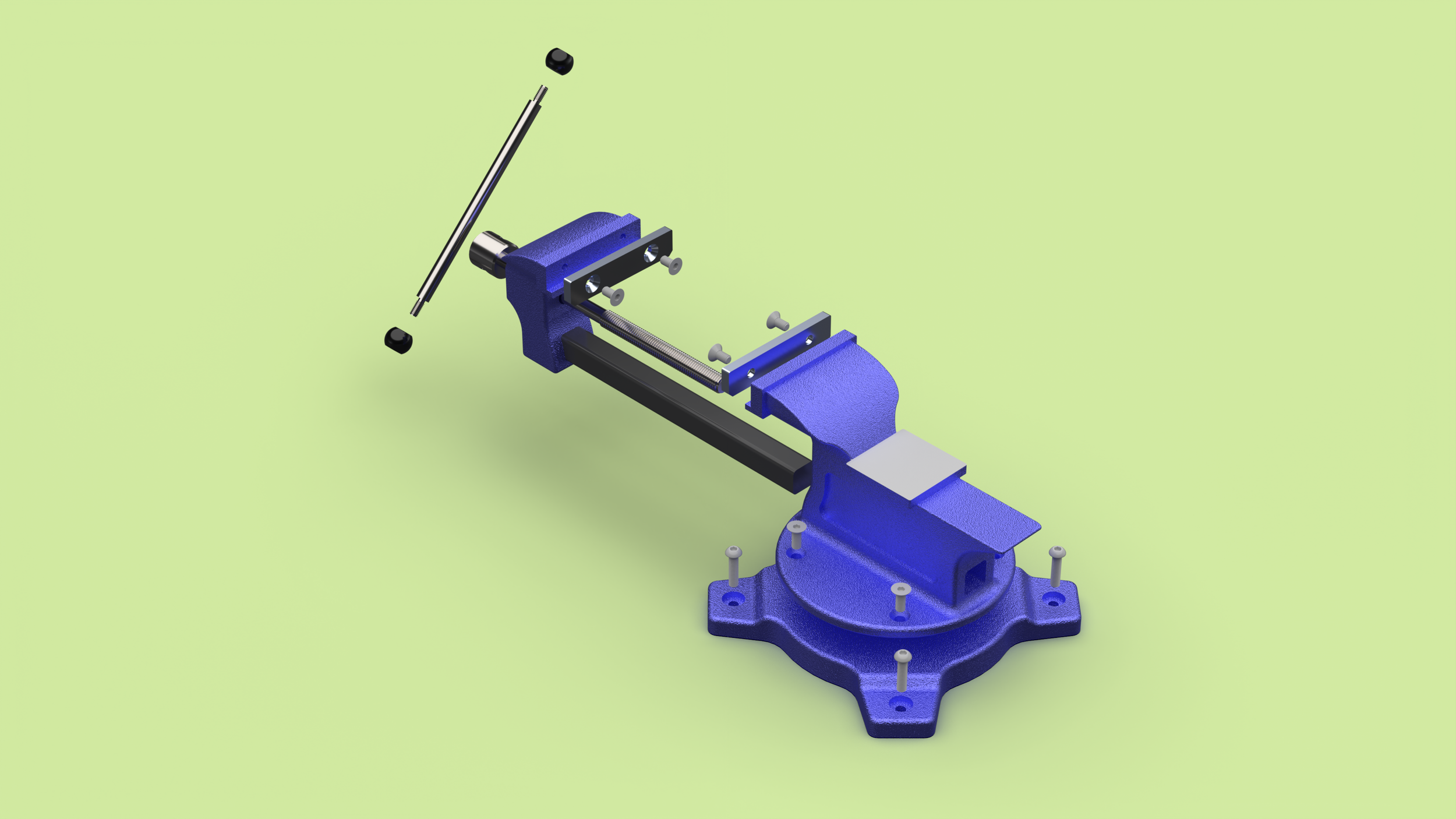

Rotating Base

Material: Cast iron or steel alloy for strength and vibration damping.

Functionality: Allows 360° rotation for flexible positioning of the workpiece.

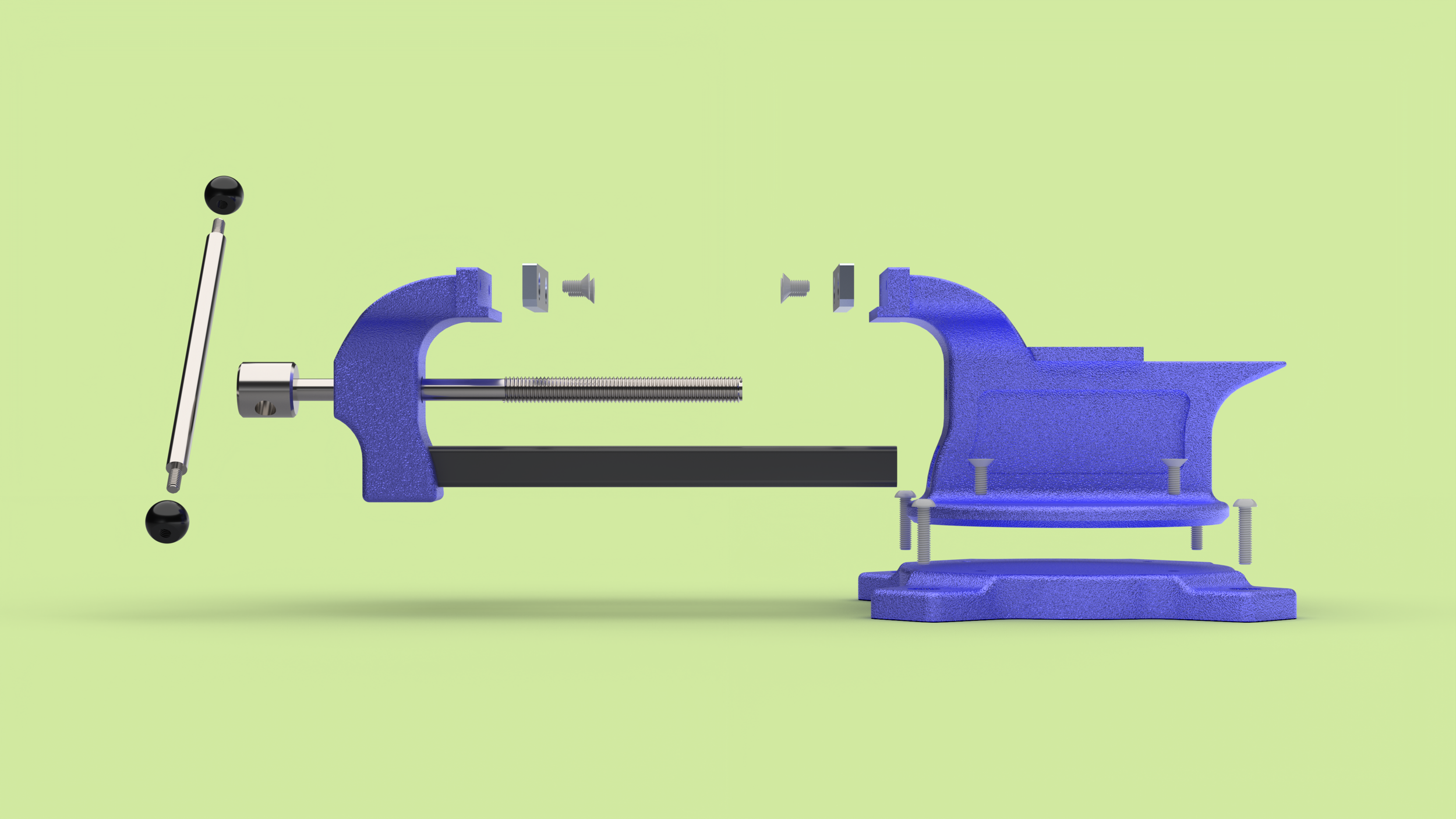

Jaws

Configuration: One fixed jaw and one movable jaw.

Jaw Width & Opening: Designed to accommodate a range of part sizes, from small components to medium-sized assemblies.

Clamping Mechanism

Handle: Chrome-plated steel rod with knobs for grip and torque control.

Threaded Screw: Precision-machined for smooth operation and consistent clamping force.

Safety Stops: Prevent over-tightening and protect internal threads.

Main Body

Construction: Solid metal frame (painted blue for corrosion resistance and visibility).

Design Considerations: Compact footprint to save workspace.