Weld Design Services for Strong Structural Connections

Design for Welded Assemblies

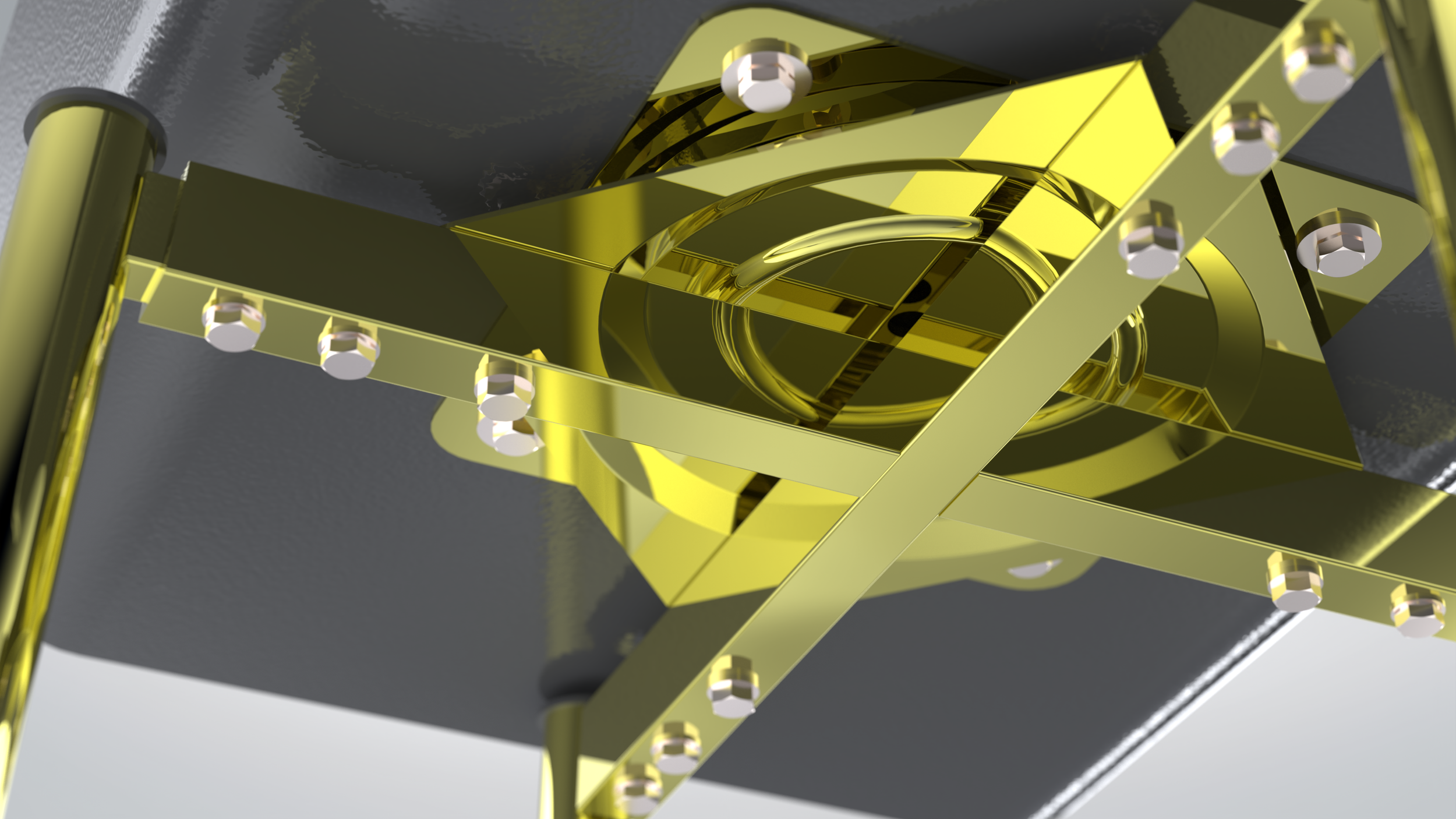

FormaSharp specializes in designing robust welded structures using SolidWorks Weldments and advanced CAD workflows. From machine frames and support brackets to custom metal fabrications, we create assemblies that are optimized for strength, manufacturability, and cost-efficiency. Our models include accurate profiles, cut lists, and weld-ready geometry tailored for fabrication shops.

CAD-Driven Welded Assemblies Built for Strength, Simplicity & Standards

Weld Joint Design

We’re fluent in the language of welds. Our team designs with a range of joint types including:

Fillet welds

Bevel groove welds

Plug and slot welds

Edge and corner joints

Code-Compliant Detailing

FormaSharp integrates welding codes and standards directly into our design process by working with you. We’re familiar with:

AWS D1.1 for structural steel

AWS D1.3 for sheet steel

Our drawings include proper weld symbols, callouts, and notes that align with inspection and fabrication requirements, ensuring your project meets regulatory expectations.

Applications Across Industries

FormaSharp’s weldment designs may be used in:

Industrial automation

Agricultural equipment

Construction and infrastructure

Custom metal fabrication

Steel Fabrication and Welding Considerations

Working with steel demands an understanding of thickness variation, expansion behavior, and long-term performance. Our experience with steel fabrication and welding allows us to refine weld geometry and structural features to suit real-world mechanical demand.

We assess:

Plate thickness interactions

Reinforcement and gusset placement

Stress concentrations near weld terminations

Material selection based on toughness and flexibility

Coating or corrosion protection strategies

These considerations ensure that welded steel components remain strong and dependable in structural, mechanical, and industrial environments.

Designing for Manufacturability and Inspection

Welded structures must be easy to fabricate and straightforward to inspect. We incorporate features that simplify both processes while improving consistency across production runs.

Our documentation typically includes:

Welding symbols and specifications

Weld maps and joint details

GD&T for alignment-critical assemblies

Pre-weld and post-weld inspection notes

Recommended weld sequences

This reduces ambiguity and supports predictable, repeatable results.