Exhaust Manifold

Project Overview

This project centers on the fabrication of a high-performance exhaust manifold, designed to significantly improve internal combustion engine efficiency. By streamlining the exhaust flow from the engine cylinders, the manifold reduces backpressure, enhances scavenging, and boosts overall power output. The design is tailored for performance vehicles and motorsport applications, where precision, durability, and thermal resilience are critical.

Design Highlights

Premium Material Selection

Constructed from high-grade stainless steel 304, chosen for its excellent heat resistance, corrosion protection, and long-term durability.

Suitable for high-temperature environments, maintaining structural integrity even under continuous thermal cycling.

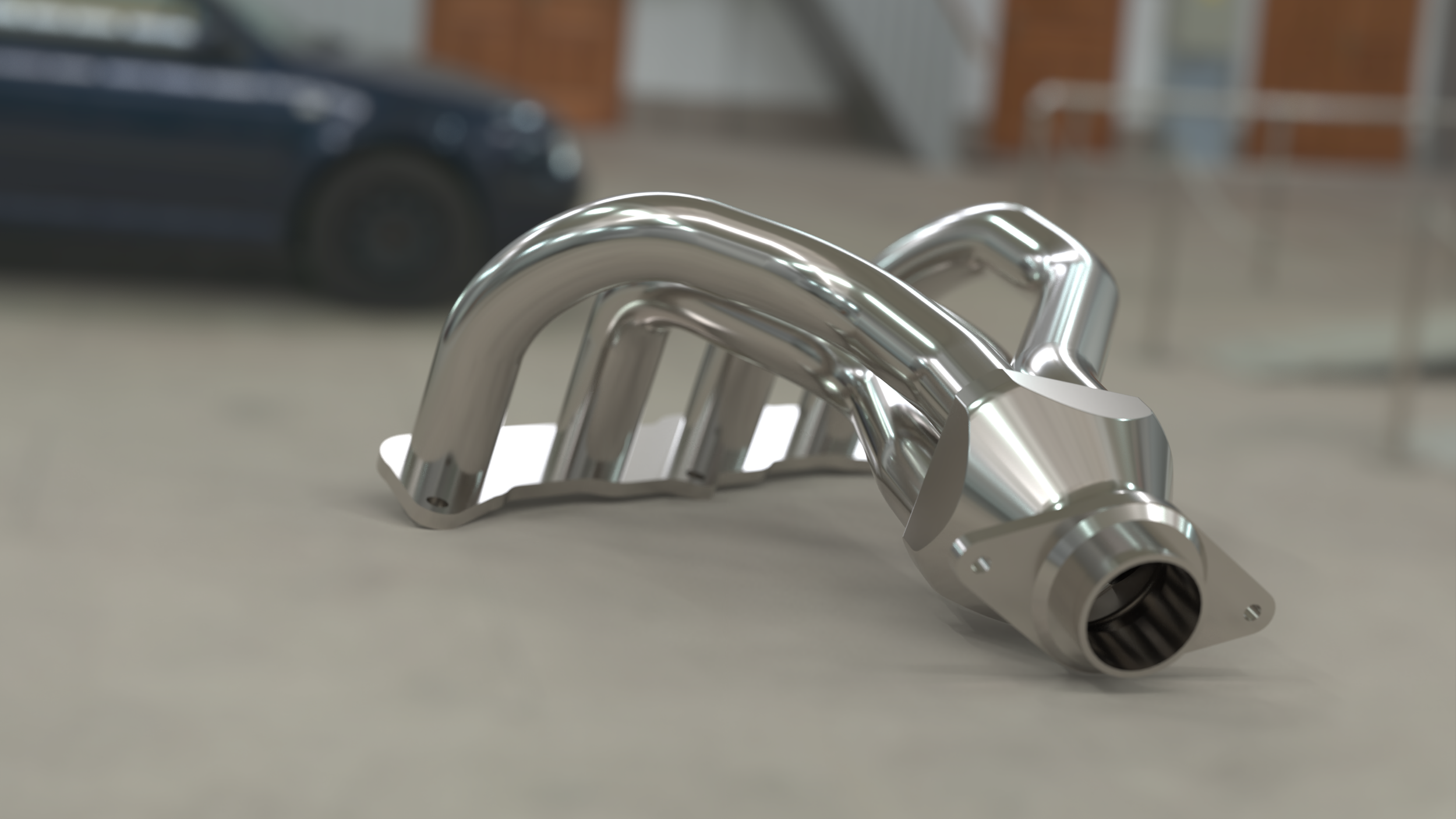

Mandrel-Bent Tubing

Each pipe is mandrel-bent, preserving a consistent internal diameter throughout the bends.

This technique minimizes turbulence and backpressure, ensuring smooth and efficient exhaust flow.

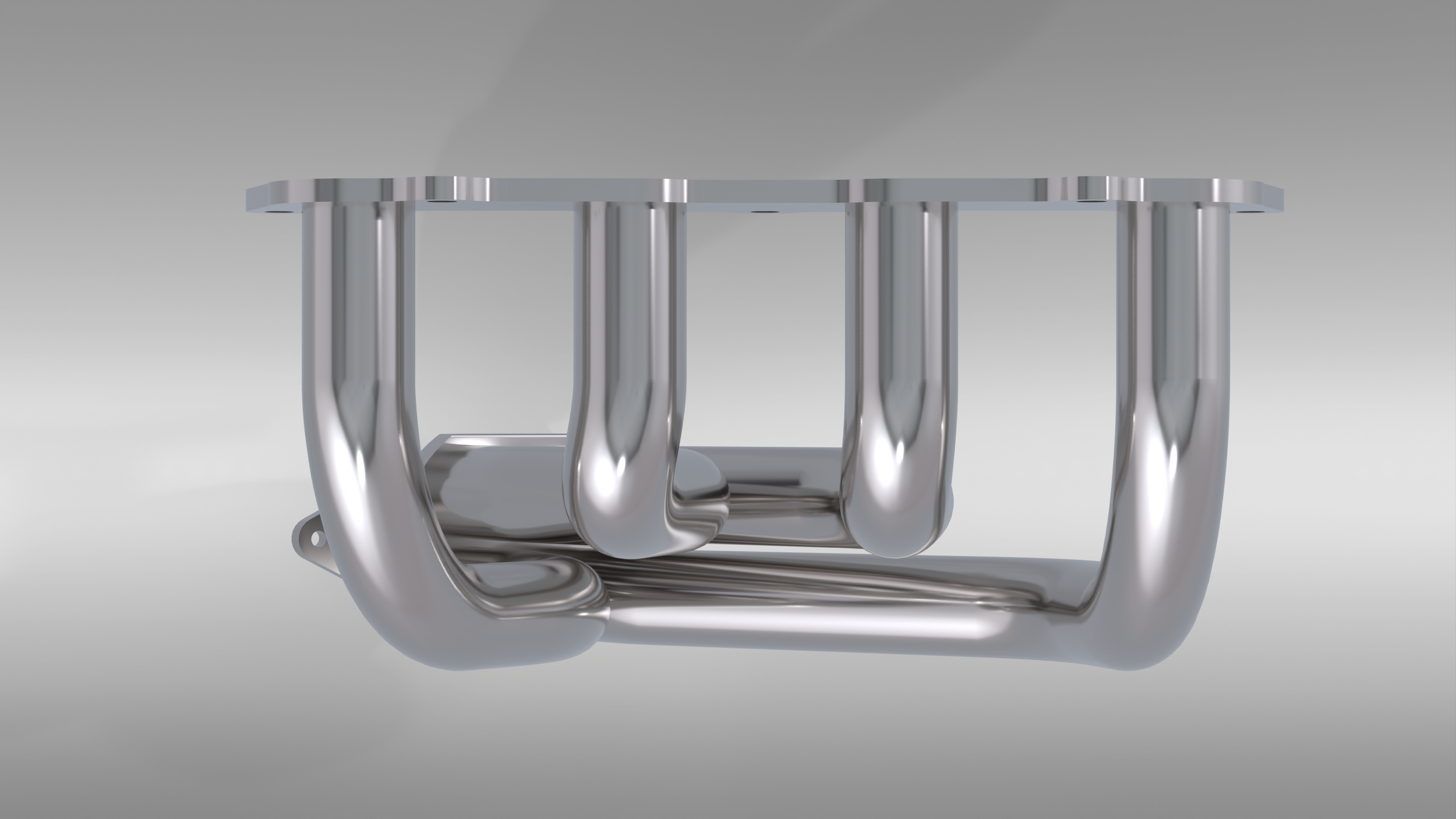

Surface Finish and Aesthetics

Finished with a polished surface, offering both visual appeal and enhanced resistance to oxidation and corrosion.

Ideal for exposed engine bays in performance builds, combining function with form.

Optimized Flow Configuration

Features a 4-into-1 collector design, where four primary pipes converge into a single outlet.

This configuration enhances exhaust scavenging, improving cylinder evacuation and increasing horsepower and torque.

Precision Flange

The manifold includes a CNC-machined flange, ensuring a perfect seal against the engine block.

Prevents exhaust leaks and supports optimal thermal and mechanical performance.

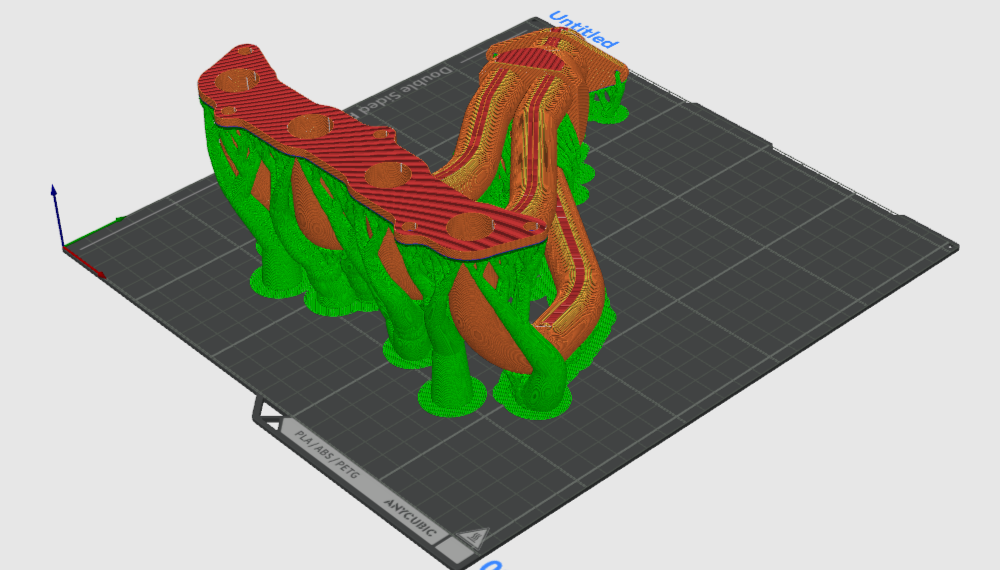

Modular and Service-Friendly Design

Its modular layout allows for straightforward integration into various engine setups, reducing installation time and complexity.

Bolt-on compatibility and accessible mounting points make it ideal for both professional tuning shops and DIY enthusiasts.