Bridging the Gap Between CAD and the Factory Floor.

Design for Manufacture

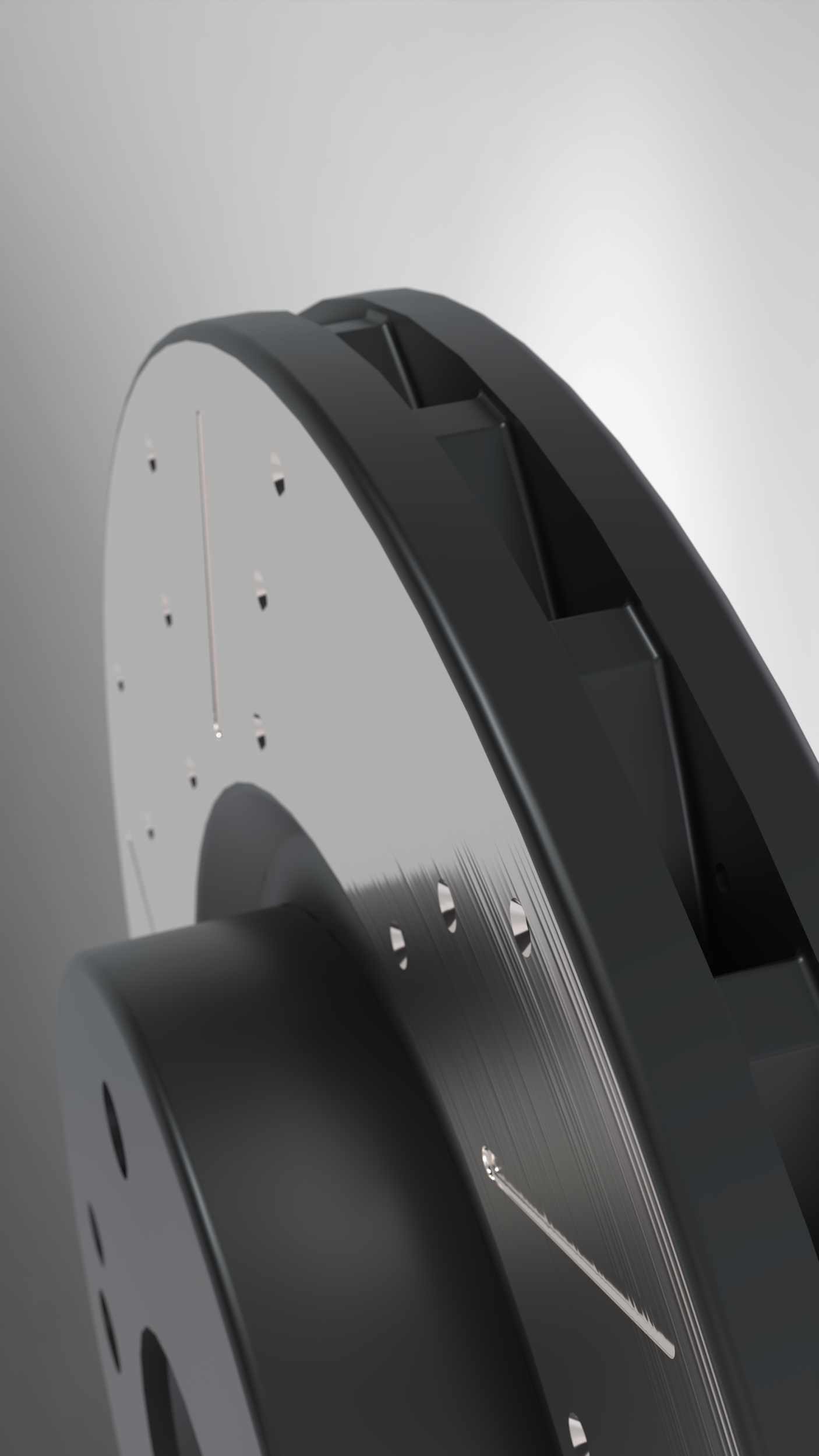

From Concept to Production—Without Compromise

At FormaSharp, we don’t just design products—we visualize them for reality. Our Design for Manufacture (DFM) approach ensures that every concept we create is optimized for the manufacturing process it’s intended for by working with your manufacturer. Whether you're prototyping a new idea or preparing for full-scale production, our designs are built to perform, built to last, and built to be made.

We understand the nuances of various manufacturing methods and integrate those requirements directly into the design phase. This means fewer revisions, lower production costs, and faster time-to-market.

Our Value Proposition

Production-Ready Designs: Every model is created with manufacturing constraints in mind.

Reduced Rework & Waste: Minimized design iterations and material inefficiencies.

Cross-Process Expertise: We tailor designs to suit specific fabrication methods.

Seamless Handoff: Clear documentation and CAD files ready for machinists, molders, and fabricators.

Manufacturing Processes We Support

FormaSharp designs are tailored for a wide range of manufacturing methods—from high-precision CNC machining to mass-production injection molding. We understand the unique requirements of each process and integrate those constraints directly into the design phase.

While we specialize in processes like CNC machining, sheet metal forming, injection molding, 3D printing, weldments, and more, we’re not limited to these. Our design expertise is adaptable, and we’re always open to working with new or specialized fabrication techniques.

If you have a unique process or production method in mind, we’re ready to design for it.

🔹 CNC Machining

Precision parts with tight tolerances

Optimized for tool paths, fixturing, and material removal

🔹 Milling / Lathe / Drilling

Rotational and subtractive processes

Designs suited for multi-axis operations and surface finishes

🔹 Injection Molding

High-volume plastic components

Draft angles, parting lines, and mold flow considerations

🔹 Sheet Metal & Forming

Enclosures, brackets, and structural parts

Bend allowances, reliefs, and flat pattern optimization

🔹 Weldments

Structural frames and assemblies

Joint design, weld accessibility, and distortion control

🔹 3D Printing

Rapid prototyping and low-volume production

Support structure planning, orientation, and material selection

🔹 Metal Fabrication

High-strength components with repeatable geometry

Grain flow alignment, die design, and material deformation

🔹 Wood Fabrication

Furniture, fixtures, and consumer products

Joinery, grain direction, and CNC routing for wood

🔹 Glass Molding

Decorative and functional glass components

Mold design, thermal stress, and surface finish control

Design Principles We Follow

Working in Industry

We Speak the Language of Production

FormaSharp works closely with fabricators, machinists, and prototyping partners to ensure your design is ready for the shop floor. We provide:

Native CAD files (SolidWorks) and neutral formats (STEP, IGES)

Detailed 2D drawings with tolerances and notes

BOMs and fabrication instructions

Support for remote and local manufacturing teams

We’re your bridge to production.

Designs That Meet Industry Requirements

Our mechanical and industrial designs follow recognized standards to ensure quality, safety, and compatibility:

GD&T (Geometric Dimensioning & Tolerancing) for precision and fit

ISO, ASME, and ANSI standards for drawings and documentation

Industry-specific compliance for medical, automotive, and consumer products

We ensure your product meets the expectations of regulators, manufacturers, and end users.