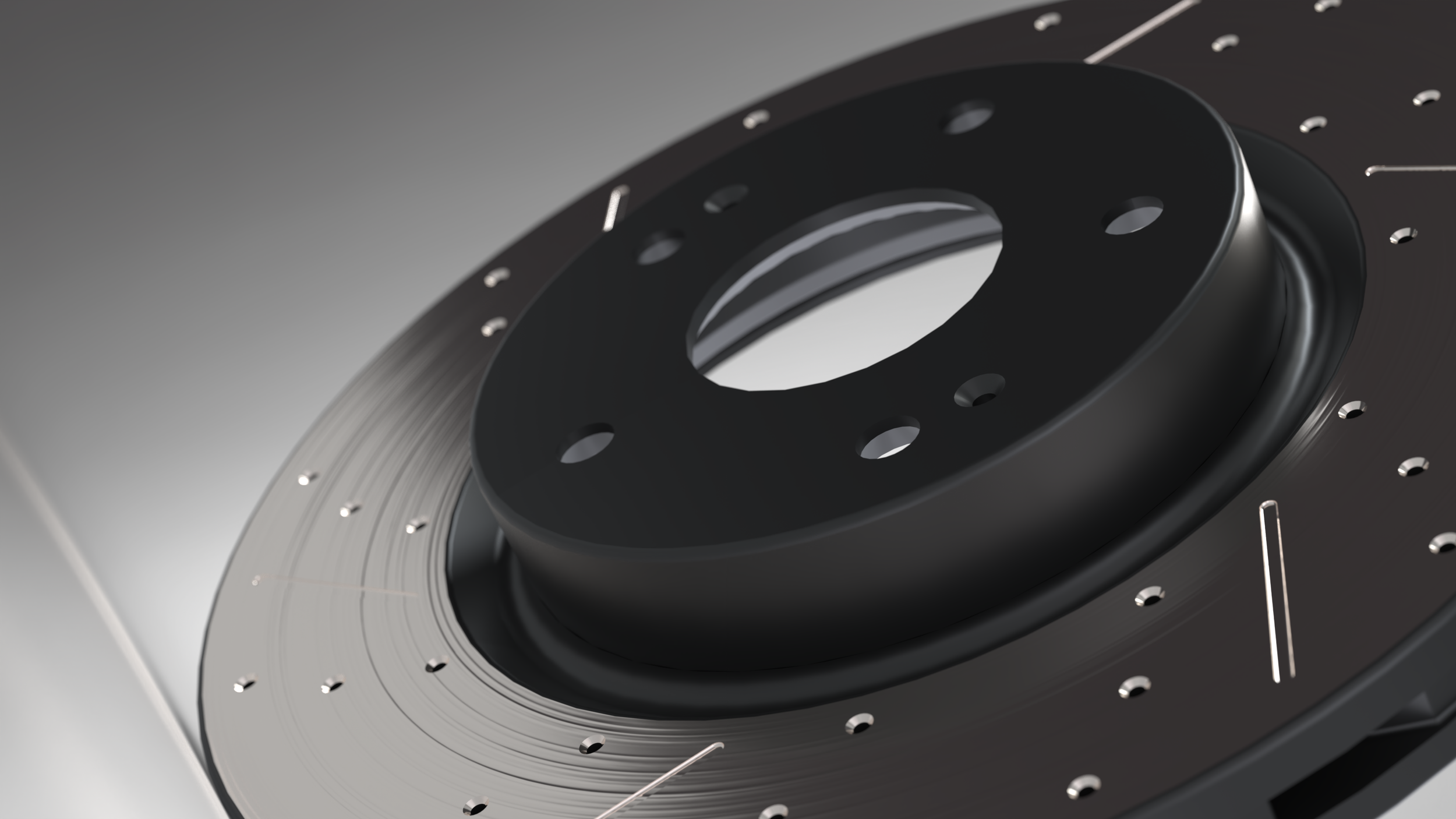

CNC Machining

At FormaSharp, we specialize in mechanical design for CNC machining. Our role is to ensure your parts are designed with precision, manufacturability, and performance in mind—ready for seamless handoff to your preferred machine shop or manufacturer. Whether you're developing a prototype or preparing for production, we create CAD models that meet the geometric, material, and tolerance requirements of CNC processes like milling, turning, and drilling.

We don’t manufacture parts or generate CAM files—but we do provide clean, production-ready CAD models and detailed 2D drawings that help machinists execute your vision with confidence. Our designs are built to meet real-world constraints, reducing costly revisions and accelerating your development timeline.

It starts with a model.

Every cut depends on it.

Design for Manufacturability

CNC machining demands thoughtful design. We create parts that are both functional and practical to machine, considering tool access, material behavior, and tolerance requirements. Our experience allows us to anticipate manufacturing challenges and design around them—saving you time and money.

We support designs for:

Metals: Aluminum, Stainless Steel, Brass, more

Plastics: ABS, Nylon, PEEK

Designed for CNC Processes: Milling, Turning, and Drilling

-

Milling

CNC milling uses rotating cutting tools to remove material from a workpiece, allowing for the creation of complex shapes, pockets, and contours. At FormaSharp, we design parts optimized for multi-axis milling, ensuring tool access, proper fixturing, and efficient material removal strategies.

-

Turning

Lathe turning is ideal for producing cylindrical components with high symmetry and precision. Our designs for turned parts include features like concentric grooves, threads, and smooth transitions, tailored for compatibility with CNC lathes and rotary tooling setups.

-

Drilling

Drilling is a fundamental CNC process used to create holes with specific diameters and depths. We ensure that hole placements, tolerances, and clearances are accurately defined in our CAD models and drawings, supporting both standard and deep-hole drilling operations.